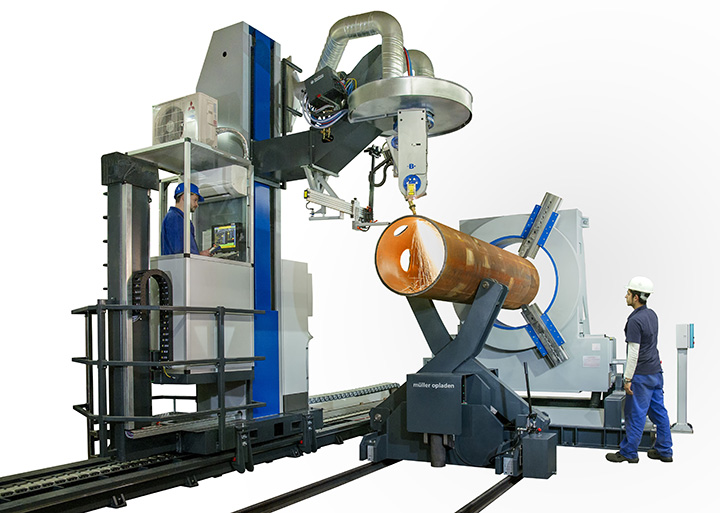

Pipe cutters are the tools of choice for plumbers when making clean pipeline cuts. Not only does the agency provide a clean cut, but depending on the pipe’s metal, it is typically quicker, cleaner, and more convenient than a hacksaw. Pipe cutting, or pipe profiling, automatic pipe cutting machine price in india, is a mechanical manufacturing operation that shapes pipes and tubes into particular configurations. Straight cuts, miters, saddles, and center holes are all examples of standard profiles.

Although its primary function is pipe cutting, specific pipe cutter machines can slot, mark, notch, angle, and even mark holes.

- A pipe-cutting machine is adaptable to a wide range of pipe materials.

- It cuts quickly, leaves no burrs, and makes a hole perpendicular to the tube’s axis.

- The self-centering clamping mechanism features stainless steel champions to accommodate various diameters.

- The pipe-cutting machine’s blade is close to the clamping system, eliminating pipe vibrations. Pipes with thin walls or tiny diameters may be cut using the device without worrying about distorted results.

- The pipe cutter is lightweight and portable, making it an ideal tool for use in the field and the workshop.

- Choice of the electric or pneumatic sawing motor

- You may upgrade the pipe-cutting machine to perform a complete range of welding operations by installing a functioning electric revolution system for controlling and welding power.

Process streamlining

Metal shavings and flaws might result when using a physical blade to cut a tube, necessitating further cleaning and shaping steps. When cutting pipes with a machine, you get almost faultless edges, and the slag from the operation can be easily collected with a waste-collecting drawer. The need for humans to complete various procedures is reduced due to the autonomous loading, aligning, and unloading features on many laser cutters.

Diverse methods of slicing

Technology’s significant degree of control and accuracy is helpful in many contexts, and laser cutting is no exception. In addition to straight vertical cuts, laser tube cutting machines may be used for various other purposes. Although conventional laser cutters can do many jobs, their cylindrical material incompatibility makes them less than ideal.

Improvements to the tube end’s strength

Using a laser pipe cutting machine has several benefits, including eliminating the need for the mechanical force during the cutting process, resulting in cleaner cuts. When a punching machine cuts through material, it usually applies pressure, which might weaken the surrounding area. Because of the precision of a laser cutter, the finished pipes should be more robust.

For Research Only

Laser tube-cutting equipment will improve productivity and efficiency, allowing your business to meet high orders for specially shaped tubes. The Offshore Lifting, Agriculture, Pipeline, Power Plant, Steel Construction, and Shipbuilding Industries may all benefit from their PipeCut machine’s vast range of pipe and profile-cutting options.

Detection of Seams

Many modern laser cutting machines include seam-detection software and use cameras and lights to tell the difference between inner and outside seams in a tube. Once the problem area is found, the machine will spin the line to fix it. These are a few examples of the many benefits of modern pipe laser cutting equipment to companies of all sizes.